Closure and Reclamation

We help mining facilities to prepare final permanent closure plans and optimize closure bonding cost estimates. Cover design methods we employ include evaporation cells, evapotranspirative covers, and resistive barrier covers. We develop reclamation programs consistent with intended post-closure land use. Germination and plant uptake studies assess the ability for native plant species to establish in the proposed growth medium (using ore, waste rock, or alluvium) in conjunction with reclamation drainage design and erosion control to contribute to developing successful re-vegetation programs.

In addition, our services include the characterization and abatement of mine-related impacts. We manage corrective actions from small soil removal projects to the design and implementation of multi-media extraction and treatment systems. We perform groundwater and vadose zone characterizations, monitoring, and computer modeling to select and design cost-effective remedies.

Engineering

DBS&A professional engineers provide specialized design expertise for mining projects. Our engineers are experienced in all phases of planning, design, and construction including:

- Planning and feasibility assessments

- Preliminary engineering reports

- Cost analysis/assessment

- Drawings and specifications

- Bid and contract documents

- Construction quality control/assurance

Examples of our engineering experience at mines include:

- Stormwater management, including collection and diversion

- Design and installation of synthetically lined ponds used to store process solutions

- Design and installation of neutralization and evaporation ponds

- Innovative cover design for tailing and stockpile facilities

- Regional groundwater extraction and monitoring system design, installation, and operation

- Design, installation, and operation of seepage collection systems (e.g., cutoff walls and pump-back systems)

Environmental Site Characterization and Remediation

DBS&A has conducted environmental site characterization and abatement activities at numerous sites, including active and abandoned mines. We have designed and installed more than 2,000 environmental wells. Examples of our environmental characterization experience include the following:

- Determination of the extent of environmental impacts

- Groundwater and vadose zone monitoring

- Tailing, leach stockpile, and waste rock characterization studies

- Acid rock drainage (ARD) prediction and mitigation

- Aquifer testing and analysis

- Groundwater flow and contaminant transport modeling

- Use of geophysical survey applications

We perform characterizations, monitoring, and computer modeling to select and design cost-effective remedies. We manage corrective actions from small soil removal projects to the design and implementation of multi-media extraction and treatment systems.

Hydrogeology and Geochemistry

DBS&A performs a wide range of hydrogeologic and geochemical services, including:

- Design and installation of wells and drilling oversight

- Surface water, groundwater, and vadose zone monitoring, including sampling for inorganic, organic, and isotopic constituents

- Installation of field instrumentation for real-time data collection

- Aquifer testing in supporting of mine dewatering, water supply, and contaminant transport studies

- Detailed mineralogical and geochemical studies, including material characterization, acid rock drainage (ARD) assessments, and tailing and leach pad instrumentation

- Baseline studies to establish background environmental conditions

- Groundwater and geochemical modeling to predict future conditions or provide better understanding of current conditions

- Statistical evaluation of environmental data

Our computer modeling capabilities include state-of-the-art codes for the simulation of groundwater flow and geochemistry. We are experienced in the simulation of complex hydrogeologic conditions encountered at mine sites, such as perched water bodies, underground workings in combination with open pits, and zones of preferential flow. We offer simulation of water quality using comprehensive hydrogeochemical analysis for open pits, leach pads, and in-situ leach operations.

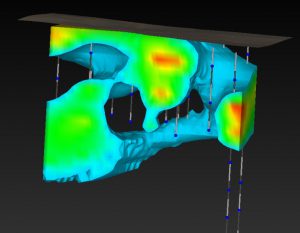

Our illustrations, 3D models, and animations range from conceptual renderings to data-driven visual interpretations. Using geographic information system (GIS) and Mining Visualization SystemTM tools, DBS&A creates coherent and comprehensive interpretations of surface and subsurface conditions, including visualizations of ore bodies, contaminant plumes, water levels, wells, borings, and block models.

Permitting and Regulatory Compliance

Effective and timely permitting is critical for mine operations and expansion. We help our clients navigate and maintain compliance with state and federal regulations, such as the U.S. Environmental Protection Agency’s (EPA) National Pollutant Discharge Elimination System (NPDES) permit compliance, including Multi-Sector General Permit (MSGP), Municipal Separate Storm Sewer System (MS4) requirements, and Construction General Permit; National Environmental Policy Act (NEPA), Clean Water Act (CWA), Clean Air Act (CAA), and many state regulatory programs. DBS&A has successfully negotiated with regulatory agencies to permit mine operations, resulting in reduced mining costs and increased operation life of the mine. Examples include:

- Permitting in-pit leach stockpiles and the backfilling of existing pits with waste rock to shorten haul distances and expand leaching operations

- Developing alternative abatement standards for groundwater to support permit compliance as well as the management and treatment of mine water

- Modifying and renewing state permits to reflect changes in mining operations

- Assisting with the development of regulations, such as the New Mexico Copper Rule

- Providing expert testimony at public meetings and at hearings to support permit acquisitions or variances

DBS&A’s natural resource team includes experienced biologists, ecologists, and permitting specialists with the expertise to perform biological assessments, biological evaluations, habitat conservation plans, ordinary high-water mark determinations, wetland delineations, and mitigation and monitoring plans. We perform all aspects of evaluations for NEPA compliance and have experience with impact analysis for land use, natural resources, threatened and endangered species, water resources, socioeconomics and environmental justice, hazardous materials, air quality, noise, visual resources, and cultural resources.

Soils and Geotechnical Laboratory Analyses

DBS&A’s nationally recognized Soil Testing and Research Laboratory performs testing to support closure activities. The lab is certified to determine the geotechnical, saturated, and unsaturated properties of soils and geologic materials. DBS&A’s soil testing and geotechnical analyses follow procedures established by American Society for Testing and Materials (ASTM), the American Petroleum Institute, and the American Society of Agronomy.

In addition to using standard test methods, our scientists develop tests to answer unique questions of importance to our clients. For example, to help a mining client in South America optimize lithium extraction, the lab developed a method to estimate extractable brine from site-specific geologic and solution samples.

Water Management and Supply

DBS&A conducts water supply evaluations to optimize the use and management of water sources, including the engineering of required infrastructure, well field development, mine dewatering assessments, and acquisition and permitting of water rights.

DBS&A also develops site-wide water balances using the GoldSim dynamic systems modeling platform or other tools. Such models help mines manage process solutions and meet their water demands. Our staff has created GoldSim models to evaluate the effects different operational and climate scenarios have on leaching operations and future water requirements. We work with mine personnel to obtain site data and prepare model components so that the models accurately reflect facility operations.

Enhanced Metal Recovery/ Injection Leaching

The GLA companies use Enhanced Metal Recovery (EMR) to help mining clients access previously unrecoverable gold, silver, and copper. EMR is a heap leach injection process that accelerates the recovery of target metals, and recovers metals that were unrecoverable utilizing traditional surface application leaching. Injection leaching has resulted in recovery of tens of thousands of additional ounces of ore for our mining clients, adding tens of millions of dollars right to their bottom lines. Learn more on GLA’s website.